GeoffL

Full Member

- Messages

- 909

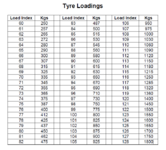

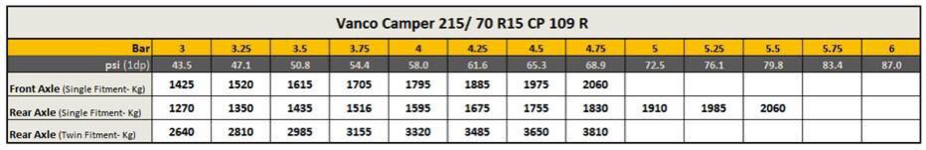

OK. Plugging the tyre info and max axle weights into a calculator gives 80psi for the rear and 70psi for the front. While I use the van in a variety of loadings, most of the variation is over the rear axle and I suspect that with a pile of astronomy gear in the rear lockers, two bikes on the back and an 80% full fresh water tank, I'll be close to max rear axle loading. Since the max axle weights are 2120 and 1850, you'd think that Fiat would have given something similar to the figures I calculated?